CERATIZIT wins innovation award for the additive manufacturing of carbide parts

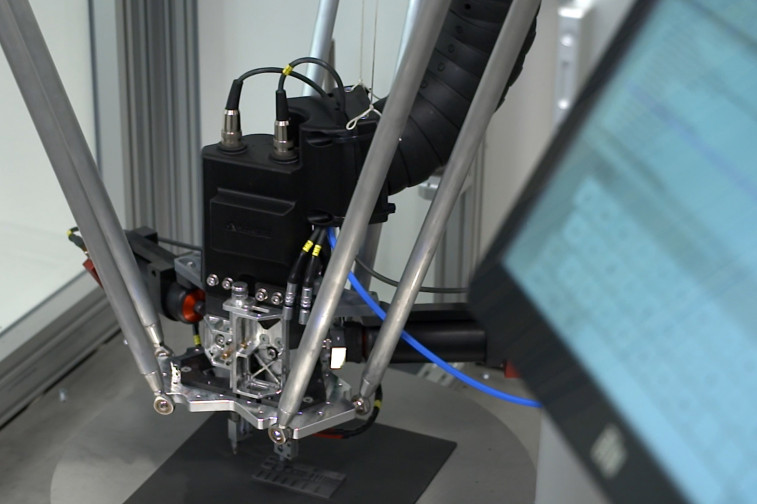

The CERATIZIT Group has won the 2020 Innovation Award of the FEDIL business federation in the ‘Process’ category for the development of a new process for the additive manufacturing of tungsten carbide-cobalt. Thus, the Luxembourg hard materials specialist has established itself as a pioneer in the additive manufacturing of cemented carbide components.

The additive manufacturing of components made of plastic, steel and other materials has continued to grow in importance over the last few years. However, in the case of cemented carbide, there had not been a reliable process so far that achieved the same standard of quality as the manufacturing processes that had been established and optimised over decades. With its newly developed process, CERATIZIT not only achieves the customary quality of products manufactured by pressing and machining but can also respond better to customer requirements, as Head of R&D Dr. Ralph Useldinger explained:

“Additive manufacturing of carbide products provides us with more flexibility in terms of implementing customer requirements and opens new design possibilities, which we can use to offer our customers highly optimised, individual solutions in minimum time.” This also includes active support in optimising product design, as Useldinger emphasised.

Faster delivery at lower costs

One of the main advantages of the additive manufacturing of cemented carbide is the time and cost savings during the critical ramp-up of products in small batches and of high complexity such as the manufacturing of prototypes. By producing the geometry directly from the design software, 3D printing allows for the fast planning and implementation of projects, without the use of production-intensive shapes and dies as well as expensive, diamond-tipped tools which are needed for the machining of carbide parts. This undoubtedly saves a lot of valuable time and money, particularly in the development of prototypes.

More freedom of design

The second big benefit of additive manufacturing is the wider range of possible shapes due to the direct production of free-form contours which go way beyond the limits of traditional manufacturing processes. Thanks to the new process, geometries can now be manufactured that were previously considered unfeasible. These include, for instance, structures that have undercuts or areas inaccessible to cutting tools such as cavities and channels inside the finished body which cannot be accessed from outside at a later stage. This innovation enables a higher degree of component complexity as well as a deeper level of integration while at the same time reducing the number of assemblies and individual components.

Potential customers interested in working together as development partners to find optimised solutions for their applications can get in contact with the relevant team in Luxembourg via our email address.

Communiqués liés

Apex Group boosts Saudi team with appointment of key executi...

Leading global financial service provider Apex Group has grown its team in the M...

Gcore raises $60 million in series A Funding to drive AI inn...

Gcore, the global edge AI, cloud, network, and security solutions provider, toda...

Luxair sélectionne le plus gros modèle des Boeing 737 MAX ...

Boeing et Luxair annoncent aujourd'hui que le transporteur régional européen c...

Global Wealth Report 2024 - La croissance revient à 4,2%, c...

Partout dans le monde, les gens s'enrichissent progressivement, et pas seule...

Luxair et lux-Airport font face à une panne technologique m...

Luxair et lux-Airport souhaitent informer le public sur la panne technologique m...

Apex Group Americas continues to expand its business develop...

Apex Group Ltd. (“Apex Group”) – global financial service provider - has a...

Il n'y a aucun résultat pour votre recherche